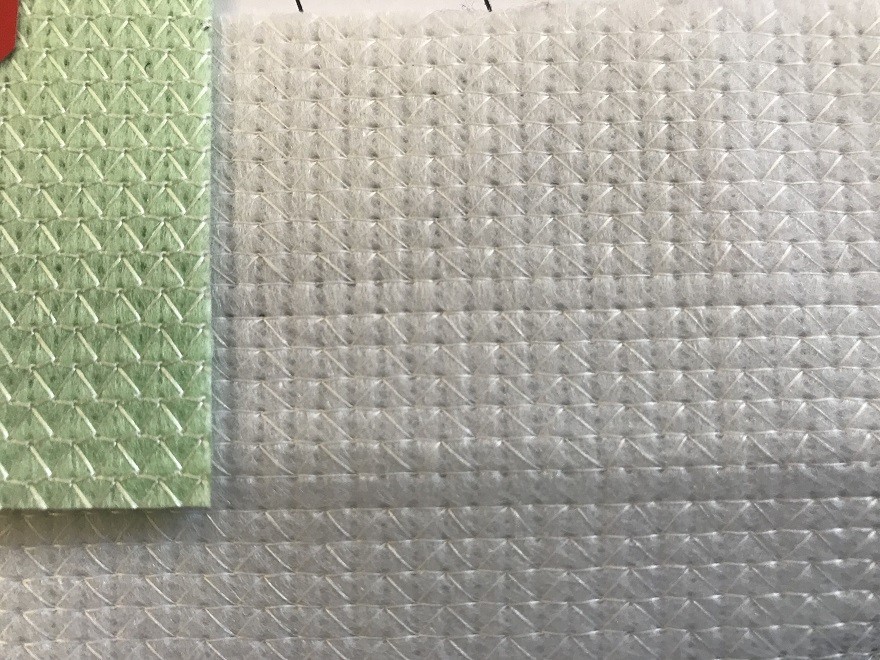

Synthetic Leather Base

Polyester needle punched nonwoven base fabric for synthetic leather ,are sheet or web structures bonded together by entangling fiber or filaments mechanically, thermally or chemically. Its usually made of 100% recycled polyester or dipped with recycled glue for better uniform shapes. We produce it by high speed and advanced needle punched machine,to make sure our fabric is with enough density for oven processing.

Category:

Polyester needle punched fabric

Get Quote

Product description

Our polyester needle punch nonwoven fabrics are highly durable and are used for various functions such as absorbency, liquid repellence, resilience, stretch, softness, strength, flame retardancy, wash ability, cushioning, thermal insulation, acoustic insulation, filtration, use as a bacterial barrier and sterility. These properties are combined with specific jobs to maintain a good balance between product use life and cost.

Synthetic Leather is made by transfer coating process, using transfer coating machines. PVC/PU Coating process is done by applying thin layer called Top Coat of PVC/PU Paste over special type of paper called Embossed release paper using coating blade. A synthetic leather is made by a impregnating a non-woven or woven textile with an aqueous polyurethane dispersion comprised of a nonionizable polyurethane and an external stabilizing surfactant. Our interlining fabric are needle punched and provide great support as base fabric to Synthetic Leather.

Specifications :

- GSM : 120 - 400

- Thickness: 0.6-1.2mm

- Width : Up To 120 "

- Color : White & Black ,No Bleeding while processing

- Finish : Soft /Semi-Hard/ Hard

- Packing: Heavy paper core supported.No zig zag trimming at both side of width .

Advantage:

- Uniform

- Durable

- High tear and tensile strength

- High Density

- No color bleeding

- Stable in Oven processing

- Absorbent for dipping

- GRS certifcated polyester nonwoven .

Next

Related Products

Get product quotes for free